Automotive Case Study

Contents

Description

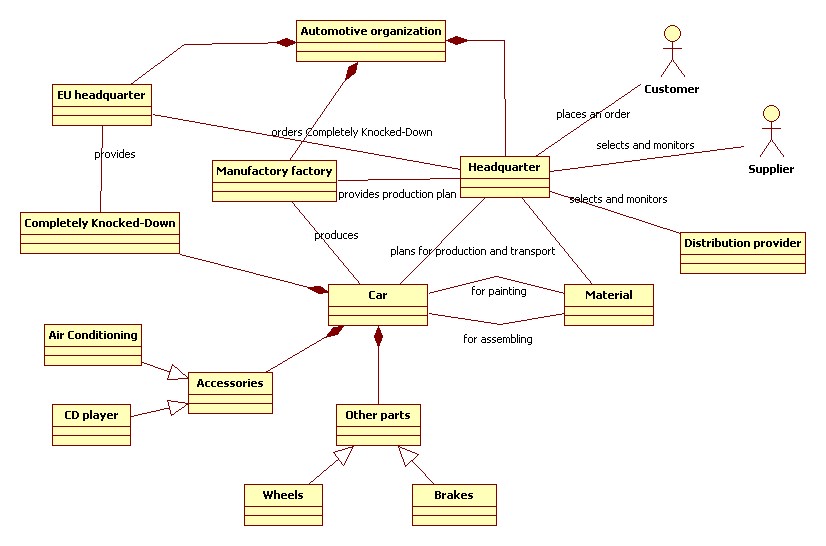

Automobile Incorporation (Auto Inc), located in South East Asia, is a local branch of a large enterprise in the automobile industry in Europe. Its incorporation comprises of a regional headquarter in Singapore, a manufacturing factory in Vietnam, several regional distribution and logistics provider, and several warehouses located in different countries in South East Asia. Auto Inc sells automobile products to retail customers in the surrounding countries. The main business tasks of the manufacturing factory include importing and assembling CKD (Completely Knocked-Down) automobile body parts from the EU headquarter supplier, importing and assembling other parts (like wheels, brakes, seats, etc.) from regional suppliers, painting, integrating accessories (e.g. air conditioner, CD player, etc), testing and releasing the final products. Beside the mandatory CKD parts which must be imported from the overseas headquarter (from now on we will call them main sources), the other material and (semi-finished) products can be ordered from the regional suppliers in surrounding countries (from now on, we will call them local sources). This local sourcing strategy is indeed efficient regarding the reduction of costs and risks. Depending on the product specifications, the assembling, integrating and painting tasks use varying materials and products, and might be executed in disparate ways as well. Different distribution logistics providers participate in the incorporation to provide the transportation of finished products from the manufacturing factory to the warehouses, and from the warehouses to the retail customers. The providers are selected according to the transportation routes and rules. The following figure illustrates the global business scope of the service network in our scenario. It highlights the main actors of the case study and the interactions, concerning both material and information flow, that occur among them. We used this figure as a basis to identify the dependencies in the SDD.

Business Goals and Domain Assumptions

in the following we show the business goals and the domain assumptions

JSZxP4 <a href="http://oxhdddpngliu.com/">oxhdddpngliu</a>, [url=http://uavfdfamupbc.com/]uavfdfamupbc[/url], [link=http://cjgfhcmfhthk.com/]cjgfhcmfhthk[/link], http://myawixesjhmb.com/

Domain Assumptions

| Field | Description |

|---|---|

| UniqueID | IBM-DA-01 |

| Short Name | Adoption of SCOR and RosettaNet PIPs |

| Type | Domain assumption |

| Description | The case study scenario is constrained with following assumptions:

|

| Rationale | RosettaNet and PIP are well known standards in the area of supply chain. Their usage would increase the likehood that Auto Inc will be able to interact with a high number of stakeholders in the value network. |

| Involved Stakeholders | Customers, Suppliers, Distribution providers, Auto Inc. Headquarter, Auto Inc. Manufacturing factory, Auto Inc. EU Headquarter |

| Supporting Material | None |

| Priority of accomplishment | Should have. |

| Field | Description |

|---|---|

| UniqueID | IBM-DA-02 |

| Short Name | Boundaries of the case study |

| Type | Domain assumption |

| Description | The case study is limited to the management of everything that is triggered by a order process. On the contrary, the following aspects are considered to be out of scope: customer assist, customer relationship management, contract management, promotion and after-sale support, product return process. |

| Rationale | The company is modernizing its information system but would focus on a few aspects at a time as otherwise the required budget would be too high. |

| Involved Stakeholders | Customers, Suppliers, Distribution providers, Auto Inc. Headquarter, Auto Inc. Manufacturing factory, Auto Inc. EU Headquarter |

| Supporting Material | None |

| Priority of accomplishment | Should have |

Domain Analysis

urRAwW <a href="http://nnieavhrrtik.com/">nnieavhrrtik</a>, [url=http://znibqtfdzdez.com/]znibqtfdzdez[/url], [link=http://iviurqmxzdsr.com/]iviurqmxzdsr[/link], http://otizjkwqcusg.com/

Domain Model

The next figure describes all main concepts in the case study application domain as well as the relationships among them. In particular, it highlights the fact that a car is composed of CKD (Completely Knocked-Down) parts plus some other parts that are provided by local suppliers. The car also includes accessories, again, acquired through local suppliers and requires the usage of various materials for the assembling and painting process. Local suppliers are chosen according to their capacity and reputation. Compliance rules and risk can influence this choice as well. In particular, the following aspects are taken into account:

- The introduction of Government import rules prohibiting the import of particular kinds of goods from particular countries.

- The high dynamicity of tax rules in some countries, where they can change monthly or weekly.

- Variations in the Free Trading Zone (FTZ) of some country. These are zones where trading is tax-free. However, they could be changed frequently thus resulting in new regulations to be taken into account.

- The triggering of some internal rules that aim at protecting against critical situations. For instance, after 3 successive transactions with the same supplier, if the supplier does not reduce the price or introduce any new special offer, Auto Inc may want to consider to switch to other suppliers.

- The delay of delivery time due to bad weather, delay at border customs, etc.

Scenarios

| Field | Description |

|---|---|

| UniqueID | IBM-SC-01 |

| Short Name | Placing purchase orders and schedule products delivery |

| Related To | IBM-BG-01, IBM-BG-02, IBM-BG-03, IBM-BG-04 |

| Involved Actors | Auto Inc manufactoring factory, Auto Inc EU headquarter, Supplier |

| Detailed Operational Description | The main supply chain process can be summarized as follows:

In order to perform these operations, the above steps rely on the business services.

|

| Problems and Challenges | See the above description. |

| Additional Material |

| Field | Description |

|---|---|

| UniqueID | IBM-SC-02 |

| Short Name | Plan Supply Chain |

| Related To | IBM-BG-01 |

| Involved Actors | all Auto Inc headquarter |

| Detailed Operational Description | Sales and operations plans are carried out monthly. Their foresight horizon is normally for the next 12 to 18 months. The headquarter analyzes the customer forecasts and sales performance in each region, and then releases a supply unit plan. This supply unit plan indicates how many products are planned for delivery in each warehouse in the next 12-18 months. However, because of the financial constraints and limited manufacturing capacity, the Enable Plan 10 process will constrain this supply unit plan and release the constrained plan to the next P4 process. |

| Problems and Challenges | None |

| Additional Material |

| Field | Description |

|---|---|

| UniqueID | IBM-SC-03 |

| Short Name | Tactical planning |

| Related To | IBM-BG-01, IBM-BG-02, IBM-BG-03 |

| Involved Actors | all Auto Inc headquarter |

| Detailed Operational Description | The tactical planning activities comprise Plan Deliver (P4), Plan Manufacturing (P3), and Plan Source (P2), which foresee the plans for the next 12- 14 weeks. Inputs for the P4 process are the constrained unit forecast from P1 and the unconfirmed sale orders from each region provided by the Deliver process D1. The P4 process decides then how many products should be delivered from each warehouse and informs the D1 process. As we see within the D1 process, the D1.3 step decides to fulfill the prioritized orders and postpone the other ones to the next round. The result of planning delivery in P4 process leads to the new replenishments orders for the warehouses, which will be sent to the manufacturing factory. |

| Problems and Challenges | None

|

| Additional Material | None |

| Field | Description |

|---|---|

| UniqueID | IBM-SC-04 |

| Short Name | Plan Manufacturing |

| Related To | IBM-BG-01, IBM-BG-03 |

| Involved Actors | all Auto Inc headquarter |

| Detailed Operational Description | The Plan Make (P3) process takes into account these orders and the already scheduled production plan, and then decides how many products

should be produced more for the near future. The result of this process is a new production plan that should be scheduled in the M1 process (Make-to-Stock). Last but not least in the planning phase, the P3 process must compensate the materials it consumed for the previous productions, by means of passing the material requirements to the Plan Source (P2) process. The P2 process considers these material equisitions with the already ordered material amounts, and then decides the volume of materials that should be sourced and stocked. The P2 process results in a scheduled material requisitions that will be fulfilled by the Source-To-Stock (S1) process. |

| Problems and Challenges | None |

| Additional Material | None

|

| Field | Description |

|---|---|

| UniqueID | IBM-SC-05 |

| Short Name | Plan Manufacturing |

| Related To | IBM-BG-03, IBM-BG-04 |

| Involved Actors | all Auto Inc headquarter |

| Detailed Operational Description | The process described by this scenario is responsible for selecting suitable suppliers, purchasing goods, transferring products into materials, and, lastly, stocking materials. The Auto Inc and its Headquarter supplier operate in the inventory replenishment strategy. This means that if there is a demand for main automobile parts, the purchasing department will send a notification of material release (PIP4D1) to the Headquarter and then receive an Advanced Notification of Shipment (ASN) (PIP3B2) to schedule the receipt.

For other automobile parts and accessories, Auto Inc can place orders at the regional suppliers. The order placement is defined with the PIP3A4 and the acknowledgement should be sent back to Auto Inc with PIP3A4 as well. As soon as the products are ready for shipment, the suppliers will send an ASN (PIP3B2) to the Auto Inc. Pointing out at the role of some external business services, the interaction with them is needed for data management, performance measurement, and performance assessment. In particular, records of purchase and replenishment orders are used to analyze the statistical performance, or to keep track and detect the risks of the current orders. Some typical KPIs such as Order-To-Acknowledgement, Order-To-ASN, etc. are measured with the records. In particular, if the Order-To-Acknowledgement and Order-To-ASN are not received or returned too late, the process will schedule new material demand and place new supply order in order to ensure the amount of source materials in stock for future production. We assume that there is no need to cancel the old order in this case. Sources will still be imported excessively. Only the reputation of supplier will be deducted. The business services also provide the information needed to select the best suppliers to place purchase orders. The selection criteria are based on the following elements:

Suppliers Management subprocess (ES10) maintains information about the current product catalogue (including prices and availability) of all suppliers, and hence can provide an ordered list based on price and availability.

criteria. The Suppliers Management subpreocess (ES10) also maintains the statistical information about the suppliers and can provide a ranking list of the suppliers, based on performance, reliability and quality.

cannot hold, or the suppliers seem to yield too many risks, Auto Inc might have to choose other suppliers, even though they could be less efficient. The Risk Management subprocess (ES9) estimates the risk of importing goods from each supplier and provides also the ranking list of the suppliers.

|

| Problems and Challenges | See the detailed operational description. |

| Additional Material |

|