Wine Production Case Study

Contents

Description

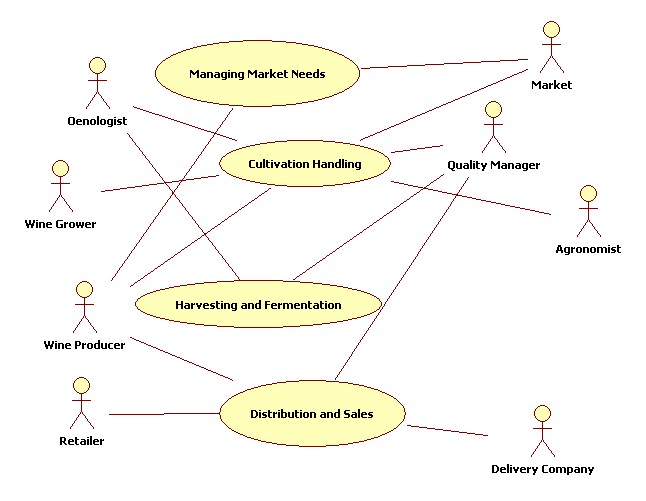

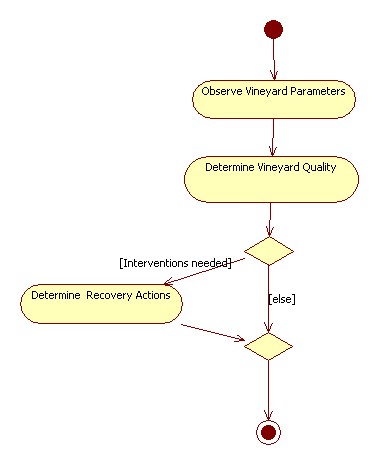

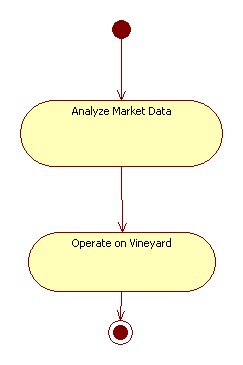

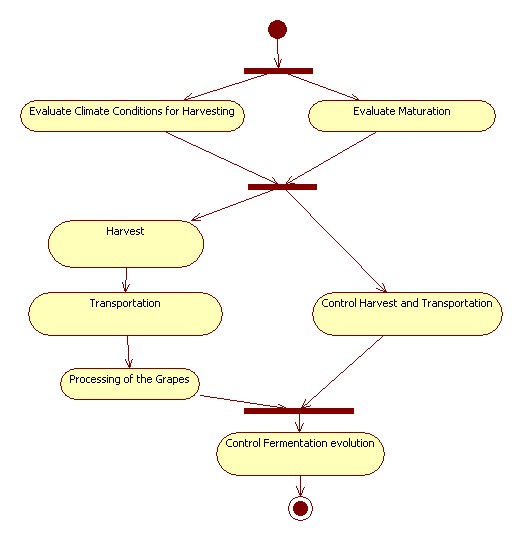

The following case study illustrates a scenario, proposed by Donnafugata, related to the wine production. It involves a Wine Producer who wants to maximize his production in order to adapt it according to the monitored market needs. Other actors of the scenario are the Quality Manager, the Agronomist (i.e., an expert of a branch of agriculture which deals with field-crop production and soil management) and the Oenologist (i.e., an expert of wine and wine production). They have to observe the vineyard parameters and to react to critical conditions that may happen during the cultivation phase. Critical conditions may be represented by overcoming the threshold for some particular environmental parameter. The case study also shows the processes involving the harvesting of the grapes and the logistics to deliver the product to retailers.

Business Goals and Domain Assumptions

In this sections the Business Goals and the Domain Assumptions for the current case study will be reported.

Business Goals

| Field | Description |

|---|---|

| UniqueID | WINERY-S-BG1 |

| Short Name | Observe Market Needs |

| Type | Business Goals. |

| Description | Starting from the domain information, the system shall provide a way to infer critical conditions from the analysis of market needs. It shall react in an automatic way to those critical conditions, both selecting predefined reactions and inferring reactions from a knowledge base. Standard reactions are provided in the scenarios and in the domain sections. |

| Rationale | Maximize sales volume. |

| Involved Stakeholders | Quality Manager |

| Conflicts | None |

| Supporting Material | |

| Priority of accomplishment | Must have. |

| Field | Description |

|---|---|

| UniqueID | WINERY-S-BG2 |

| Short Name | Observe vineyard cultivation |

| Type | Business Goals. |

| Description | The system shall provide a way to infer critical conditions from observing vineyard parameters. It shall provide a way to react in an automatic way to those critical conditions, both from selecting predefined reactions and inferring reactions from a knowledge base. Notifications to the Quality Manager, Oenologist and Agronomist shall be included in such predefined reactions. Other standard reactions are provided in the scenarios and in the domain sections. |

| Rationale | Maximize sales volume and wine quality. |

| Involved Stakeholders | Quality Manager, Oenologist, Agronomist |

| Conflicts | None |

| Supporting Material | |

| Priority of accomplishment | Must have. |

| Field | Description |

|---|---|

| UniqueID | WINERY-S-BG3 |

| Short Name | Observe maturation, fermentation and harvesting |

| Type | Business Goals. |

| Description | The infrastructure shall provide: a way to infer critical conditions from observing vineyard parameters; a way to react in an automatic way to those critical conditions, both from selecting predefined reactions and inferring reactions from a knowledge base. Notifications to the Quality Manager are included in such predefined reactions, especially if the critical conditions require manual interventions. Other standard reactions are provided in the description of the case study. Moreover, the Quality Manager shall be able to control quality parameters explicitly. |

| Rationale | Maximize sales volume and wine quality. In particular, this business goal handles the management of the critical conditions during phases following cultivation. |

| Involved Stakeholders | Quality Manager, Oenologist |

| Conflicts | None |

| Supporting Material | |

| Priority of accomplishment | Must have. |

Domain Assumptions

| Field | Description |

|---|---|

| UniqueID | WINERY-S-DA1 |

| Short Name | The system to be should be driven by a self-managing business process |

| Type | Domain assumption |

| Description | The overall business process must be designed such that it shall perform self-management, that is, it shall implement the so-called MAPE cycle, that adheres to the scenario related to this assumption. In the MAPE cycle, the execution of the business process is based on a paradigm that involves resource Monitoring, collected data Analysis, intervention Plan, and action Execution. In the case of the proposed scenario, monitoring comes from the physical infrastructure (see next assumption), and the remaining parts of the paradigm must be implemented by the self-managing business process, which permits to define intervention plans and action executions after a critical condition detection as required by the related scenario. In this approach, detection of market changes and reaction to these changes shall be implemented as a particular instance of the MAPE cycle within the autonomic infrastructure. |

| Rationale | See Description. |

| Involved Stakeholders | Quality Manager |

| Conflicts | None |

| Supporting Material | |

| Priority of accomplishment | Should have. |

| Field | Description |

|---|---|

| UniqueID | WINERY-S-DA2 |

| Short Name | Vineyard is equipped with a wireless sensor and actuator network. |

| Type | Domain assumption |

| Description | This assumption arises from the necessity of examining parameters of vineyards, which are spatially distributed among cultivation fields. This infrastructure can be seen at the business level from two possible points of view: by a process manager component of a workflow engine or from a query layer infrastructure that offers the ability of programming events generation to deploy directly into the sensor networks. Sensors are needed to observe quality attributes of grapes during the phases of the

production process. |

| Rationale | A distribute Wireless Sensor Network (WSN) infrastructure shall be able to sense the environment of vineyards and collect data. |

| Involved Stakeholders | Quality Manager, Agronomist |

| Conflicts | None |

| Supporting Material | |

| Priority of accomplishment | Could have |

| Field | Description |

|---|---|

| UniqueID | WINERY-S-DA3 |

| Short Name | Time between harvesting and processing should be limited |

| Type | Domain assumption |

| Description | This assumption is a very simple constraint on the business process, that requires that the time between harvesting and processing of the grapes must be limited, typically within one hour, or it must be related to specific requirements of a particular production. |

| Rationale | Maximize the quality of the final product. |

| Involved Stakeholders | Quality Manager |

| Conflicts | None |

| Supporting Material | |

| Priority of accomplishment | Must have |

| Field | Description |

|---|---|

| UniqueID | WINERY-S-DA4 |

| Short Name | Logistic is supported through a RFID system. |

| Type | Domain assumption |

| Description | This assumption constrains the design of the physical and logical infrastructure for the observing and querying of temperature during the distribution phase. Moreover each bottle has associated a RFID, each pallet has associated a RFID data logger. In this case, since it is necessary to track and record the temperature information of moving packages, RFIDs and data loggers are suggested to be used. Moreover, to provide an uniform method for querying in such a physical architecture, a query layer for pervasive infrastructure should be used, such as PERLA. Finally, this infrastructure should be interfaced with the self-managing business process, in order to use it as a source for reacting to possible critical events regarding distribution. |

| Rationale | See Description. |

| Involved Stakeholders | Delivery Company, Retailer |

| Conflicts | None |

| Supporting Material | |

| Priority of accomplishment | Could have |

BxldWe <a href="http://lfkinwqhgveb.com/">lfkinwqhgveb</a>, [url=http://nhexazpvupts.com/]nhexazpvupts[/url], [link=http://mzwebasohodq.com/]mzwebasohodq[/link], http://ehqmcnjgljmh.com/

Scenarios

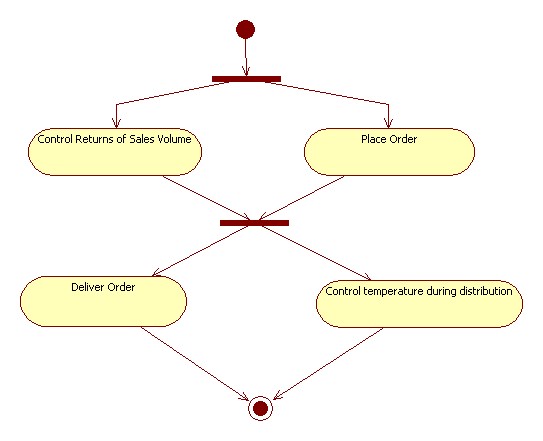

The figure shows the general use-case diagram for the Vineyard case study.